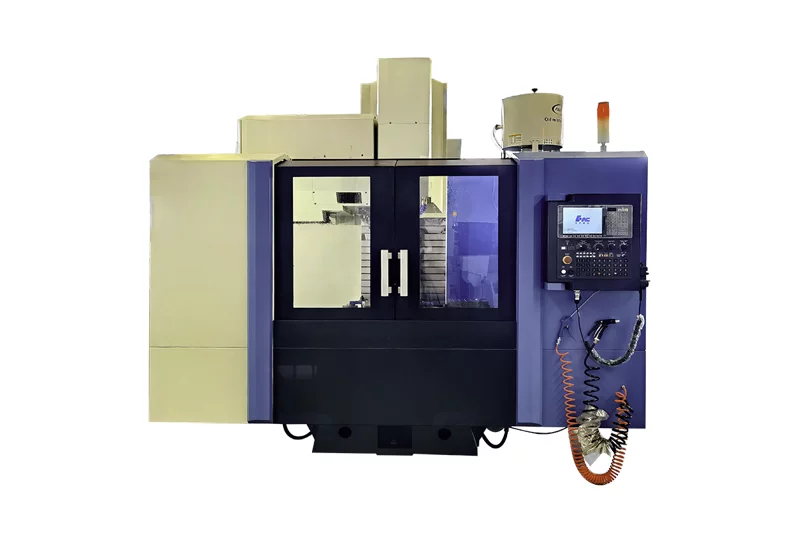

Vertical CNC Machining Center

Models List

-

VMC850B

-

VMC1000B

-

VMC1300B

-

VMC1600B

-

VMC2100B

Description

Machine Features

- The structure of the machine tool is-analyzed with ANSYS at all stages from foundation design to grantee high speed and high precision continuous machining. A simulation testing for deformation produced when the center of machine tool bears load is conducted to guarantee excellent bending rigidity of machine tool.

- The gear type spindle variable speed device provides powerful torque during operation at low speed and guarantees stable rotation during operating at high speed so as to enable wider machining range. By enlarging thickness and diameter of spindle ends and flanges, the spindle with roller bearing not only strengthens all factors related to spindle system, but also improves cutting performance via clamping force of powerful tools.

- Automatic tool changer is composed of tool magazine and tool changing arms.Automatic tool changer is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic tool changer and other reasons on precision. Tool selection adopts the method of fixed address in the shortest path. All tools return to original position, therefore, the problem of collision between large-size tools is only considered in initial installation. Two-way tool magazine adopts the shortest path.

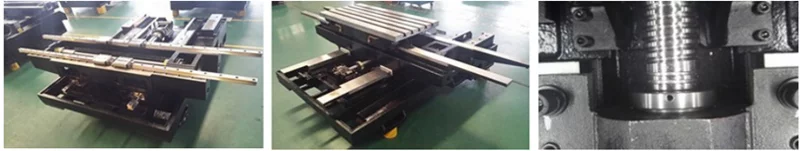

Structure

- The machine body structure has oil-water separation , reduce the pollution of the waste cutting fluid

Material

- Line rail extension , reduce shield running noise , prolong the service life of the shield

Bearing

- Double protection of the bearing , prevent damage of oil pollution resulting in abnormal bearing

Working Function

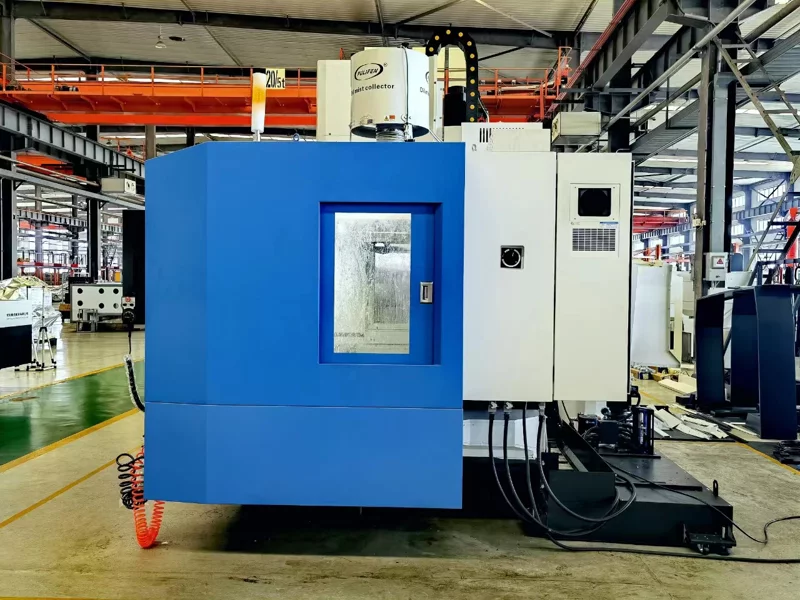

Assembly Workshop

Product Specification

| Item | VMC850B | VMC1000B | VMC1300B | VMC1600B |

|---|---|---|---|---|

| Worktable Dimensions mm | 2200x800 | 1700x800 | 1400x700 | 1200x500 |

| X-Axis Travel mm | 2100 | 1600 | 1300 | 1000 |

| Y-Axis Travel mm | 800 | 800 | 700 | 610 |

| Z-Axis Travel mm | 800 | 800 | 700 | 650 |

| Max. Distance From Spindle Nose To Worktable mm | 1000 | 940 | 850 | 800 |

| Min. Distance From Spindle Nose To Worktable mm | 200 | 140 | 150 | 150 |

| Spindle Taper Shank | 7:24 BT50 | 7:24 BT50 | 7:24 BT40 | 7:24 BT40 |

| Spindle Speed r/min | 6000 | 6000 | 8000 | 8000 |

| Main Motor Torque Nm | 380 | 95.4 | 52.5 | 52.5 |

| Main Motor Power kW | 15/18.5 | 15/18.5 | 11/15 | 11/15 |

| X/Y/Z Axis Rapid Speed m/min | 18/18/18 | 24/24/20 | 24/24/20 | 32/32/30 |

| General Power Capacity KVA | 37 | 37 | 25 | 25 |

| Machine Weight kg | 18000 | 13500 | 11000 | 7000 |

| Item | VMC2100B |

|---|---|

| Worktable Dimensions mm | 1000x500 |

| X-Axis Travel mm | 850 |

| Y-Axis Travel mm | 560 |

| Z-Axis Travel mm | 650 |

| Max. Distance From Spindle Nose To Worktable mm | 800 |

| Min. Distance From Spindle Nose To Worktable mm | 150 |

| Spindle Taper Shank | 7:24 BT40 |

| Spindle Speed r/min | 8000 |

| Main Motor Torque Nm | 52.5 |

| Main Motor Power kW | 11 |

| X/Y/Z Axis Rapid Speed m/min | 32/32/30 |

| General Power Capacity KVA | 25 |

| Machine Weight kg | 6800 |