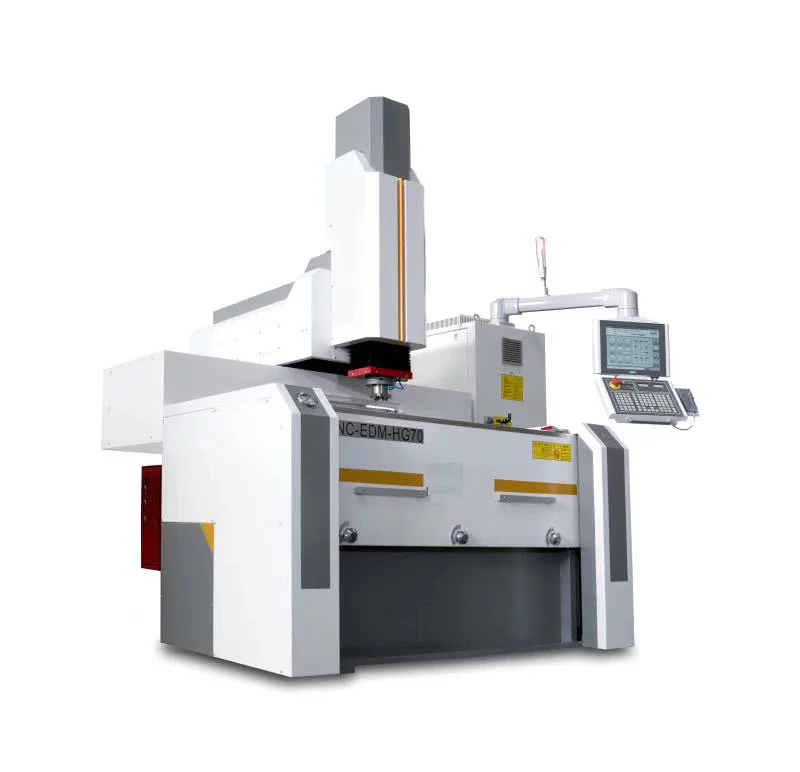

EDM Die Sink Machine

Models List

-

EDM450ZNC

-

EDM650ZNC

Main Features

- Japan SANYO DC servo motor in Z axis.

- X, Y axes adopt precise ball screw.

- Professional database system.

- High speed 400mm3/min.

- Surface roughness Ra0.8.

- Taiwan control system.

- Germany guideway coating for wear resistance.

- SIEMENS, Germany AC contactor.

- OMRON relay.

- Japan high frequency power tube.

- Harbin bearings. P5 grade.

- Castings, HT250 resin sand.

Die Sinking Forming EDM Machine Introduction

The die sinking EDM machines are used with impulse electric cabinet’s axis is driven by Japan SANYO DC servo motor, with Z axis numerical control feature.

X, Y axes adopt precise ball screw, and precision optical grating digital display shows the coordinate which make coordinates have high positioning accuracy.

Electric cabinet of EDM die sinking machine adopts the most advanced industry-specific control board, strong function, good stability, simple operation.

As long as input a few parameters, such as Z axis depth, it will select a set of suitable date from the expert database system that matches the processing, and process from the rough processing to finish once automatically.

Machine Bed

Rugged design, the first consideration is the stability of the bed. It can ensure that each part of the bed can stressed uniformly, and get the best precision under the allowed load. The structure of machine bed will help machine keep away from the influence of the workpiece in motion.

CNC wire cut EDM machine

Worktable

High-precision linear rail guideway, precise ball screw. Quick response servo and high driving accuracy. Ensure good machining accuracy and good stability.

The high-precision moving parts of machine bed and worktable using fully enclosed structure of environmental protection.

Mobile double slats table bracket and fixture, easier to use, improve machining efficiency.

ISO and CE Certified Wire EDM Machine

Movement Wire Structure

Wire cylinder use variable-frequency regulating speed technology. According to the different wire and workpiece thickness, using different wire speed. The roller bearing use grease system without maintenance to expanded three times the service life.

EDM wire cutting machine price in wire EDM machine

Lubrication System

The machine use oil lubrication system to keep the mechanical movement parts adequate lubrication and the precision of machine.

Double head type specification :

| Worktable Size | 1700 x 1000 mm |

| Travel of X, Y, Z Axis | 1600 / 1200 x 2 mm |

| Travel of Y Axis | 800 mm |

| Travel of Z Axis | 500 mm |

| Electrode Head to Worktable | 650 - 1150 mm |

| Max. Electrode Load | 400 Kg |

| Max Weight on Table | 6000 Kg |

| Max. Working Current | 100 A |

| Max. Working Speed | 700 mm³ / min |

| Electrode Wear Ratio | ≤0.3% |

| Best Surface Finishing | Ra≤0.3 μm |

| Input Rating | 8KVA |

| Output Voltage | 90 - 260 VDC |

| Work Tank Size | 2500 x 1500 x 650 mm |

| Item | EDM450ZNC | EDM650ZNC |

|---|---|---|

| Working Tank (LxWxH) mm | 1200 x 650 x 450 | 1800 x 900 x 600 |

| Table Size (LxW) mm | 700 x 400 | 1100 x 650 |

| Travel Size (X) mm | 450 | 650 |

| Travel Size (Y) mm | 300 | 550 |

| Spindle Travel (Z) mm | 200 | 300 |

| Auxiliary Travel (Z) mm | 200 | 300 |

| Distance between Spindle Nose to Work Table (Min) mm | 58 | 205 |

| Distance between Spindle Nose to Work Table (Max) mm | 450 | 805 |

| Max. Table Load (Workpiece weight) kg | 1000 | 2800 |

| Max. Spindle Hold (Electrode weight) kg | 150 | 250 |

| Oil Tank Capacity L | 470 | 1300 |

| Oil Tank Dimension (LxWxH) mm | 1260 x 780 x 450 | 1800 x 900 x 600 |

| Control Method - | DC (Japan SANYO) | DC (Japan SANYO) |

| Rated Current A | 60 | 100 |

| Machine Dimension (LxWxH) mm | 1800 x 1500 x 2200 | Actual measurements |

| Machine Weight kg | 1800 | 3500 |