EDM Wire Cutting Machine

Models List

-

ZGW32

-

ZGW40

- Precision Panasonic servo motor encoder feedback to achieve pitch compensation.

- AC servo motor drive for precise feedback compensation from processing to the end of processing.

- Advanced professional system.

- Full support for ISO Codes.

- Excellent NC Programming Orbit moving from CAD, CAXA drawing directly.

- Digital pulse generator with finish cutting.

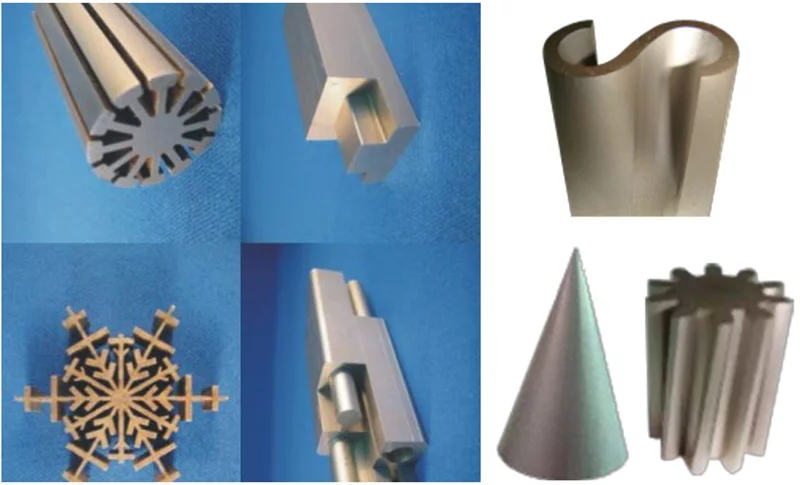

Standard cutting samples:

Big taper device cutting samples.

NC Controller:

Industry PC from Advantech Taiwan configuration:

- ICA-6806/681-400

- 128M SD

- Ethernet interface 10/100Mb

- RS232

- USB interface

- Floppy drive

- Keyboard

- Mouse

- 15" LCD

Background editing and program running, thus making it possible to edit a program while the machine is working.

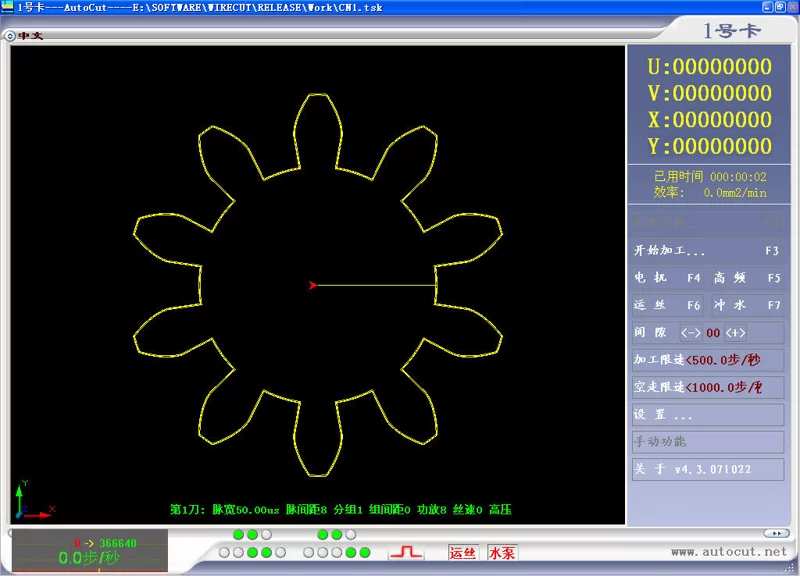

Graphic display online machining trace and workpiece profile.

Automatic graphic edit and program generation.

Translate AutoCAD files to program automatically.

ISO standard G code programming, compatible with 3B code.

HF program and control system features:

- Graphic edit based on AutoCAD, easy to learn and use rapidly and correctly.

- Advanced e-Function, connects machine to Ethernet for optimized resource management and paperless operation.

- English operation menus covering all aspects of WEDM machining technology, including electrical and mechanical presetting, parameter selection, and erosion parameters.

- Comprehensive parameter tables for different materials.

- Efficient workflow rules and peripherals for quick and high-quality workpiece production.

NC system capabilities:

- Simultaneous programming and machining.

- All operations can be performed via mouse clicks.

- Online machining trace display.

- 4-axis interpolation in 3 dimensions with automatic backlash compensation.

- Automatic data save and restore after power outage.

- Automatic home point, edge positioning, and workpiece center finding.

- Step movement for each axis.

- Drawing manipulation: rotate, zoom, mirror.

- Program reverse cut and alarm message display.

- Start working at any code line.

- Batch machining of identical workpieces.

- Backlash compensation.

- Wire lag elimination in high-speed cutting, especially for sharp angles.

- All program and control functions displayed on screen.

- Automatic program generation from AutoCAD files.

- ISO standard G code programming, compatible with 3B code.

- Automatic machine shutdown after program completion.

- Multi-cutting function.

- Automatic reverse run on short circuit.

- Wire break protection function.

- Linear and circular interpolation.

Additional Features:

- High precision ball scales and guides for rapid, smooth, and accurate movement response.

- Self-service lubrication system in pulley bearings to extend bearing life.

- Anti-wave device in wire running system for improved machining precision and extended wire life.

- Moveable clamps on worktable slides for time-saving workpiece installation.

- Integrated lubrication system in all movable parts.

- Constant force wire running structure for optimal finishing results.

- New machine body design with low, wide basement for improved stiffness and stability, built from high-quality cast iron.

- AC servo motors or step motors directly connected to ball screws for stable machine operation.

- Advanced frequency conversion technology for smooth and adjustable wire speed control.

- High-performance pulse generator for efficient machining of various materials, including alloy steels, aluminum alloys, copper, titanium, carbide, ultra-hard materials, conductive materials, and high-temperature materials.

- Anti-stripe erosion technology in generator for superior surface finishing.

- Two patented taper structures: 1) Big taper structure composed of 4 link bars. 2) Precision small taper structure with planetary movement, ensuring vertical alignment of wire and pulley for precise taper cutting.

- Modular design of power generator, NC system, and electrical equipment optimized to resist electromagnetic interference.

- Rigorous testing and inspection of each machine before sale, including 100 hours of continuous full-load testing and 100 hours of non-continuous peak-load testing.

| Item | ZGW32 | ZGW40 |

|---|---|---|

| Worktable Dimension mm | 890 x 760 | 883 x 575 |

| Worktable Travel mm | 400 x 500 | 320 x 400 |

| Max Cutting Thickness mm | 260 | 260 |

| Max Load Weight kg | 400 | 300 |

| Machine Weight kg | 1700 | 1600 |

| External Dimension mm | 1680 x 1470 x 1800 | 1600 x 1330 x 1800 |

| Max Cutting Taper degrees | ± 3 | ± 3 |

| Max Cutting Speed mm²/min | ≥ 180 | ≥ 180 |

| Best Surface Roughness µm | Rα ≤ 0.8 | Rα ≤ 0.8 |

| Electrode Wire Dimension mm | 0.10-0.25 | 0.10-0.25 |

| Worktable Minimum Feed mm | 0.001 | 0.001 |

| Machining Precision mm | 0.006 (Φ15, thickness 25) | 0.006 (Φ15, thickness 25) |