Surface Grinding Machine

Models List

-

KGS510AH/AHD

-

KGS515AH/AHD

-

KGS615AH/AHD

-

KGS620AH/AHD

Description

Feature

- Well-designed cast iron structure provides excellent dampening

- Flange mount spindle cartridge for superior side grinding rigidity

- Grinding spindle features low-maintenance preload high precision angular ball

- bearings (NSK P4 grade)

- “V” and flat type guide way which precision hand scrapped truite saddle ways for smooth and long-lasting performance

- Table guideways are hardened, ground and counter-laminated with PTFE(TEFLON) to ensure high wear-resistance

- Centralized automatic lubrication system, supplies oil to guide-ways and lead-screws as the machine operates. This system ensures all the critical components are lubricated with the right amount of oil at all times

- Separate hydraulic tank prevents heat and vibrations from being transferred to the machine

- Electric components and functional modules are well arranged and packed in the electric cabinet, making maintenance and trouble-shooting easily accessible

- Magnetic force can be adjusted

- Safety 24V control circuit power

Main Configuration of Grinding Machine

- Spindle motor: Use ABB brand which from Sweden.

- Spindle bearing: Use NSK brand P4 grade precision ball bearing which from Japan.

- Cross screw: Use P5 grade precision ball screw.

- Main electrical components: Use SIEMENS brand.

- Main hydraulic components: Use brand from TAIWAN.

Standard Accessories

| 1 | Grinding wheel |

| 2 | Wheel flange |

| 3 | Wheel balancing base |

| 4 | Wheel balancing arbor |

| 5 | Extractor |

| 6 | Diamond dresser |

| 7 | Leveling pad |

| 8 | Anchor bolt |

| 9 | Tool box with tools |

| 10 | Electric magnetic chuck |

| 11 | Cooling tank |

| 12 | Working light |

Optional Accessories

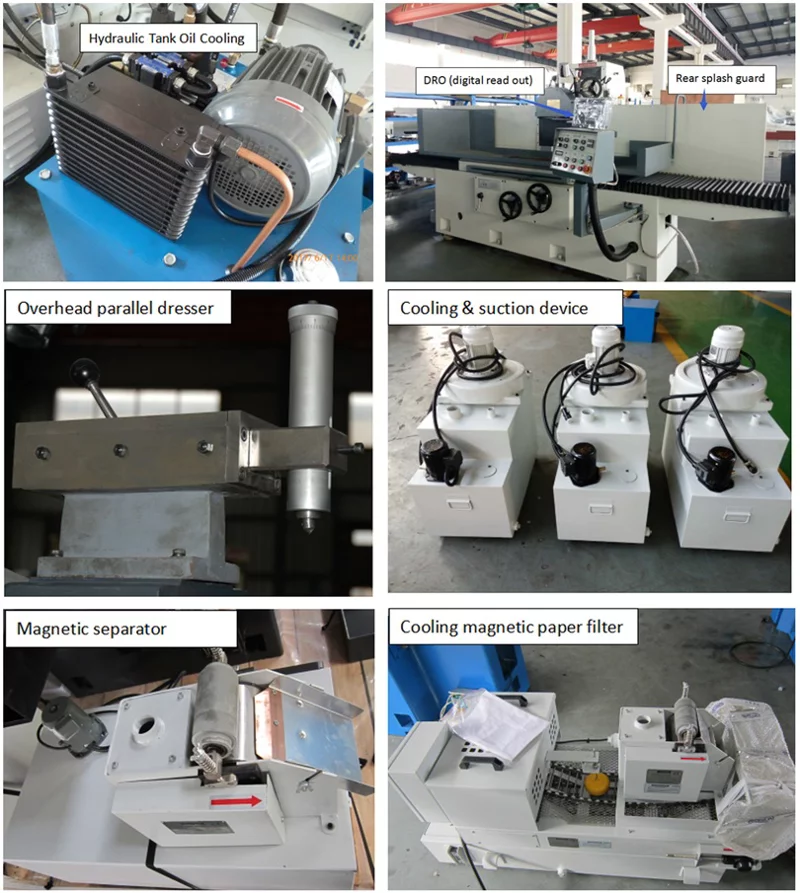

| Serial No. | Name of Article |

| 1 | DRO (digital read out) |

| 2 | Rear splash guard |

| 3 | Hydraulic Tank Oil Cooling |

| 4 | Overhead parallel dresser |

| 5 | Cooling & suction device |

| 6 | Magnetic separator |

| 7 | Cooling magnetic paper filter |

| Note | 6 and 7 , select one just OK. |

Product Specification

| Item | KGS510AH/AHD | KGS515AH/AHD | KGS615AH/AHD | KGS620AH/AHD |

|---|---|---|---|---|

| Working Surface of Table mm | 600x2000 (24"x80") | 600x1500 (24"x60") | 500x1500 (20"x60") | 500x1000 (20"x40") |

| Max. Table Travel mm | 2230 | 1600 | 1600 | 1140 |

| Max. Cross Travel mm | 660 | 660 | 570 | 540 |

| Distance Between Table Surface and Spindle Center mm | 600 | 600 | 590 | 590 |

| Max. Table Load kg | 1500 | 800 | 700 | 700 |

| Tee Slot (Number x Width) mm | 3x16 | 3x16 | 3x16 | 3x16 |

| Table Speed m/min | 7~25 | 5~25 | 5~25 | 5~25 |

| Crossfeed Handwheel (1 grad) mm | 0.02 | 0.02 | 0.02 | 0.02 |

| Crossfeed Handwheel (1 rev) mm | 5 | 5 | 5 | 5 |

| Automatic Crossfeed mm | 0.5~12 | 0.5~12 | 0.5~12 | 0.5~12 |

| Power Cross Feed (50Hz) mm | 1250 | 1250 | 1250 | 1250 |

| Power Cross Feed (60Hz) mm | 1500 | 1500 | 1500 | 1500 |

| Grinding Wheel mm | 355x50x127 | 355x50x127 | 355x40x127 | 355x40x127 |

| Spindle Speed (50Hz) rpm | 1450 | 1450 | 1450 | 1450 |

| Spindle Speed (60Hz) rpm | 1740 | 1740 | 1740 | 1740 |

| Vertical Handwheel (1 grad) mm | 0.002 | 0.002 | 0.002 | 0.002 |

| Vertical Handwheel (1 rev) mm | 0.5 | 0.5 | 0.5 | 0.5 |

| Automatic Down Feed Rate mm | 0.005~0.04 | 0.005~0.04 | 0.005~0.04 | 0.005~0.04 |

| Power Head Increment mm | 230 | 230 | 230 | 230 |

| Spindle Motor kW | 7.5 | 7.5 | 5.5 | 5.5 |

| Vertical Motor kW | 370 | 370 | 370 | 370 |

| Hydraulic Motor kW | 5.5 | 5.5 | 2.2 | 2.2 |

| Dust Collection Motor W | 550 | 550 | 550 | 550 |

| Coolant Motor W | 90 | 90 | 90 | 90 |

| Crossfeed Motor kW | 370 | 370 | 370 | 370 |

| Floor Space mm | 6200x2700 | 5810x2445 | 5810x2445 | 4445x2200 |

| Net Weight kg | 8500 | 6250 | 6000 | 5000 |

| Gross Weight kg | 9700 | 7250 | 7000 | 6000 |